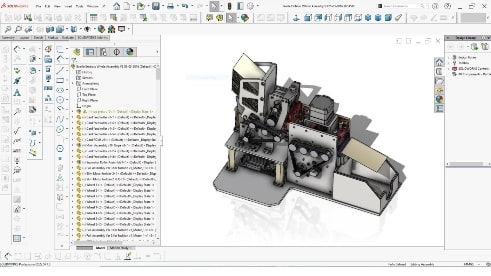

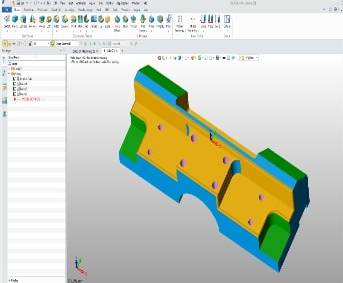

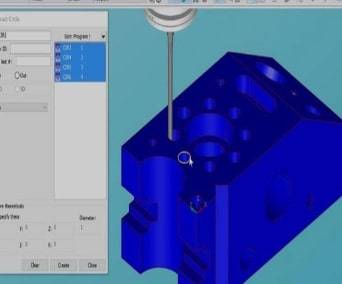

At present, JHP uses the most up-to-date software which provides three-dimensional visualization of product models & fabrication processes.

Equipped with Virtual GIBBSGAM 3D & ZW3D cam machining supporting up to 4-axis rotary positioning, and with 3D module support drawings from STEP, PRT, IGES, DXF and DWG etc., JHP is able to handle the most precise of machining needs for our customers base on any 3D model file.

JHP currently uses the most updated AutoCad System, Solidworks Professional for our Jig & fixtures, Prototype projects design and Virtual Gibbs 3D Cam system, ZW3D Cam system for our machining Processing.

OUR MANUFACTURING PROCESS CAPABILITIES

CAD Cam

Machining

Inspection

Mazak CNC Turn Mill QT-100MSY

(With Y Axis & Sub-Spindle)

Working Size: 6", I/D 52 mm, Tools - 12.

Fanuc RoboDrill CNC

(4 Axis)

Working size: 500 mm x 400 x 330, Tools - 21.

CNC Expert SV50-DT Milling Machine

(3 Axis & 4 Axis)

Working Size: 500 mm x 430 x 340, Tools - 21.

Harding CNC Milling Machine

(4 Axis)

Working Size: 480 mm x 400 x 330, Tools - 20.

CNC Expert SV760-DT CNC Milling Machine

(4 Axis)

Working Size: 700 mm x 600 x 450, Tools - 21.

VMC 850 CNC Milling Machine

(3 Axis)

Working Size: 850 mm x 500 x 500, Tools - 24.

Our quality control policy is to offer the best service to our customers by providing quality products at competitive prices and delivering them on time.

Our quality framework includes:

EQUIPMENT'S LIST

# Brown & Sharpe

Co-ordinate Measuring Machine ( CNC )

( 500 mm x 750 x 500 )

# Keyence Image Dimension Measuring System ( CNC )

( 300 mm x 200 )

# Mitutoyo Profile Projector

( 150 mm x 100 )

# Trimos Digital Height Master

( 350 mm Height )

# Mitutoyo Pin Gauges Set

# Mitutoyo Slip Gauges Set

# Mahr Surface Roughness Tester

#Granite

Surface Table

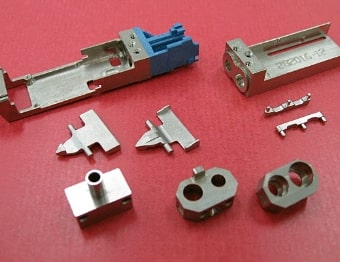

At JHP Precision Technology, we tie up with strategic partners to support their downstream operations, We also prototype and customize design as well as project collaboration.

Our Modular System

Transform Your Material Handling With The Most Advanced Automated Storage And Retrieval Systems From Modula.